Hydrogels and Metal Printing

The hydrogel, renowned online for amazing feats and spectacular properties — now one more reason to love hydrogels — it revolutionizes additive manufacturing. Researchers from EFPL (University of Ecole Polytechnique Fédérale de Lausanne) now use hydrogel structures to soak up metallic precursors known as metallic salts and use these soaked shapes to capture a form in metal so to speak. The effects of the discovery could extend from the world of material science to computing and biomedicine.

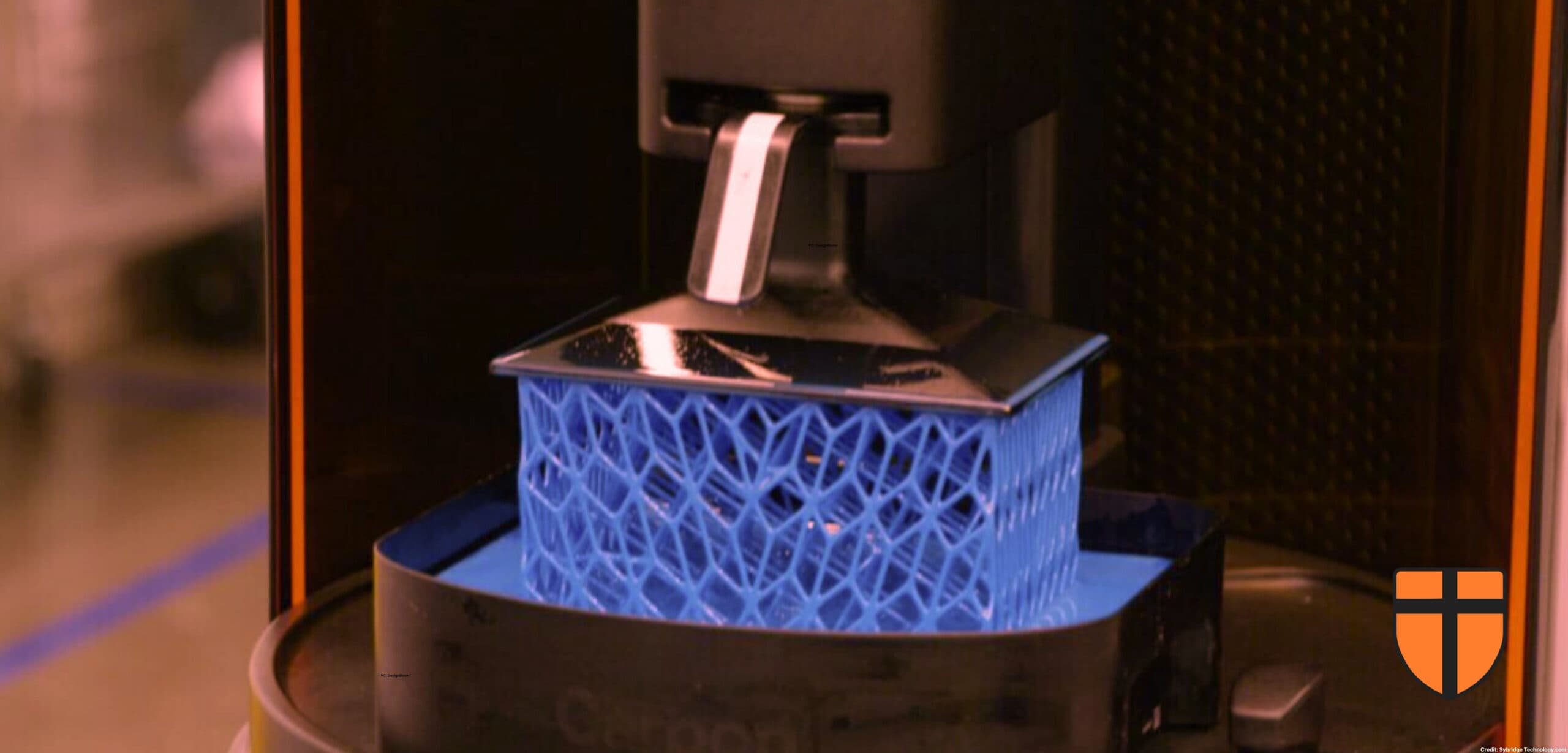

Additive manufacturing (AM) processes are distinguished from other forms of manufacturing like milling or cutting. The AM methods are seven in number: material extrusion, vat polymerization also known as photolithography, material jetting, powder bed fusion, binder jetting, and sheet lamination. Only photolithography relates to the topic of discussion at hand. This synthesis process is one where special photosensitive copolymers harden when they are exposed to certain frequencies of light. Layer by layer, line by line they take form to become a fully formed three dimensional asset.

While the AM manufacturing processes are more cost effective, time efficient, and customizable when compared to similar traditional manufacturing techniques, not all materials work well with all kinds of AM techniques. I am alluding to the fact that vat copolymerization does not work well with the intent to manufacture metallic structures. There is significant warping as well as structural insecurities in the final product, but these risks are significantly mitigated by the utilization of hydrogel substrates.

Hydrogels are aptly printed with photolithographic techniques safely, cheaply and quickly, yet there remains a step before the metal precursor is added to the material composite. This critical capacity to absorb metallic precursors like metallic salts enables its revolutionary improvements upon former methods of AM of metallic solids.

Hydrogels are copolymer chains, conducive to the vat copolymer lithography mentioned before, however, they have properties that make them indispensable to the additive manufacturing process of metallic form. Hydrogels have a great deal of water absorption; some would say that a hydrogel cell at max capacity is 99% water by weight. This enables this material to absorb a great quantity of metallic salts. These metallic salts penetrate the structure through repeated exposure in what are referred to as growth cycles. There may be 10 growth cycles to get the structure sufficiently saturated with metallic salts, to where scientists feel comfortable in burning away the hydrogel to reveal a fully functional, dense and unwarped shape to be used for its intended purpose. The finished structure boasts a density twenty times greater than the previous method’s, yet it still suffers from shrinkage of around twenty percent.

Despite its minor failings, the biggest weakness in the technology remains to be the great amount of time needed to go through ten growth cycles before the hydrogel structure is fully saturated with metal precursors. Scientists are looking to make up for this lack, through greater dependence on automation through robotic elements of the process. This process may revolutionize the way that metallic manufacturing is done, which has major implications for virtually every art and science.